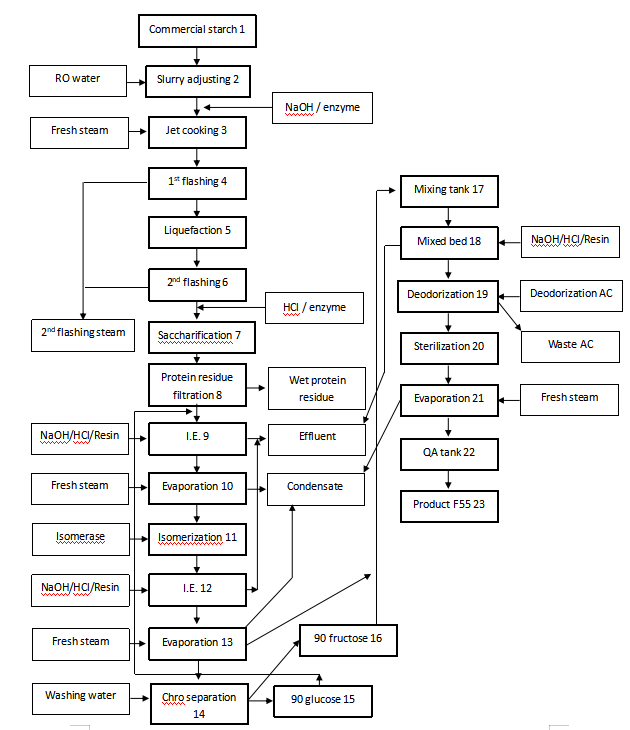

The fructose production line from HMFoodTech adopts advanced and mature production technology to process products with different fructose content according to Coca-Cola product standards, which is widely used in Coca-Cola and other soft drink industries.

The refined starch milk is sent to the adjusting tank to adjust to the required DS value. Add the food-grade NaOH to adjust the suitable value. The adjusted starch milk is sent to the feeding tank and adds the liquefaction enzyme. Through the pipeline liquefaction reactor for 1-2 hours, cooled in the flashing tank. Then, it is sent to the saccharification section.

Add the food-grade HCl to adjust the PH value to 4.5-5.0, and add a certain amount of saccharification enzyme to the reaction tank for continuous saccharification to get the required discharge.

The saccharification liquid is sent to the membrane filter system to remove the protein first. After cooling, the dextrose is sent to the I.E. system. According to the cation-anion sequence to perform the I.E. system to remove the minerals of the dextrose. The failed column was generated by NaOH and HCl.

The dextrose is sent to the evaporator after pre-heating. After getting the required DS value, it is sent to the F42 production.

The refined dextrose is sent to the feeding tank of isomerization. Add food-grade NaOH to adjust the PH value and add the MgSO4 at the same time to activate and stable the isomerase. After adjusting the temp. and flash degassing, the material is pumped into the continuous isomerization column for isomerization to get F42.

The isomerized fructose after filtration & cooling is sent to the I.E. treatment according to the cation-anion-mixed bed sequence to remove the impurities during the isomerization. The failed I.E. column is generated by the NaOH and HCl.

The fructose is sent to the evaporator for concentration after pre-heating. The DS value is 71% after concentration, namely F42 fructose. It is not only as of the product for selling but also as the raw material of the F55 fructose with suitable DS value after concentration.

After heating by the heat exchanger, the F42 fructose is sent to the chromatography system for the separation to get the F90 fructose and G90 glucose. Mix the F90 fructose and F42 fructose to get the F55 fructose.

The F55 fructose is cooled, then to the deodorization device for the deodorization. Another, the G90 glucose from the chromatography system is backed to the previous process.

The refined F55 fructose is sent to the evaporator for concentration after pre-heating to get the F55 fructose product with DS 76.5-77.5%.

The F55 fructose is sterilized first, after filtering the exogenous impurities, then filling.