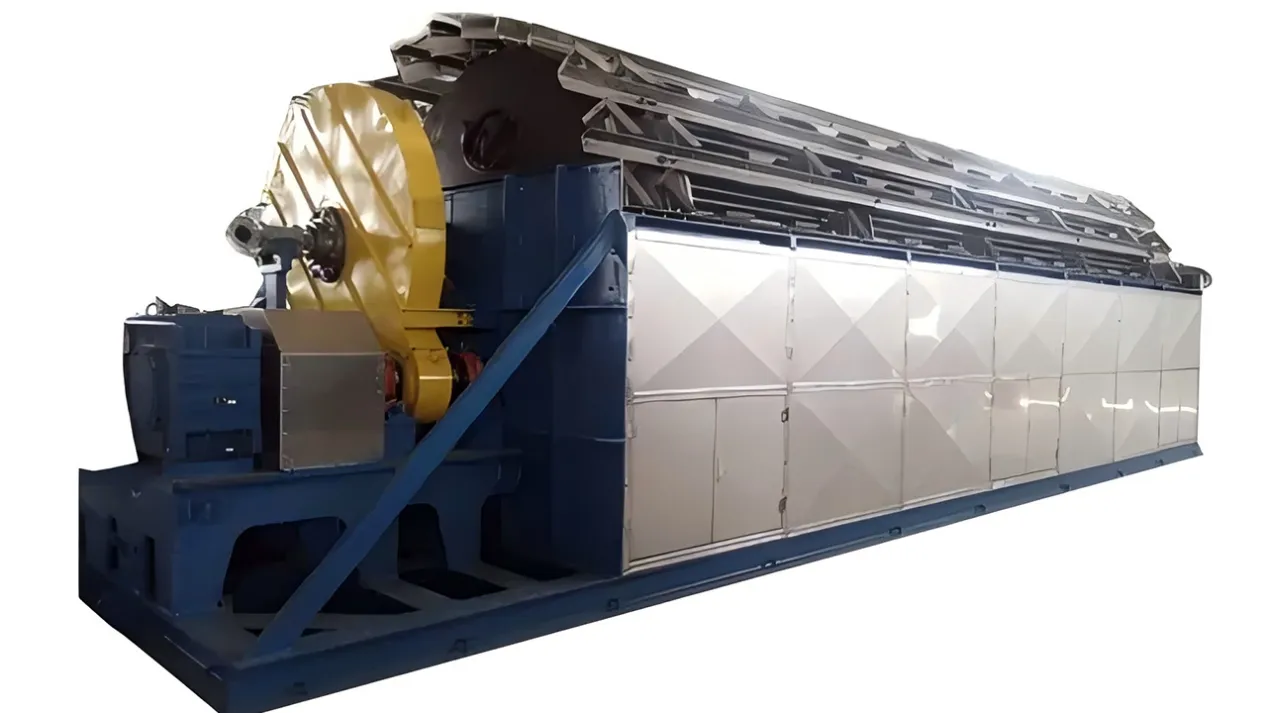

In Indirect Tube Bundle Dryer the tubes are arranged in a circumferential manner on the inner periphery of the rotating shell. This entire shell and tubes assembly is supported on tyres / rollers & driven throughsuitable gear drive. Wet feed material is fed through material inlet nozzle installed at one end of the shell of dryer. This wet feed is fed through Screw Feeder. Feed material showered on the tubes with the help of lifting blades which are mounted on the rotating shell. Steam enters in the tubes through rotating joint installed at material discharge end of the shell. Material gets dried & discharged from the material discharge ports on the shell. Vapours are removed from the feed end with the help of suction blower after separating fines in the cyclone separator. The suitable sealing arrangement is provided to prevent air leakage and product / losses.

Batch Capacities: Available in sizes ranging from 30 kg to 500 kg per batch.

Pneumatic Sealing: Inflatable silicon rubber seals for the filter bag and product container.

Explosion Protection: Built-in explosion vents and isolation valves.

Process Automation: Fully automated controls for temperature and process cycles, with batch records maintained for traceability.

FDA-Approved Filters: Washable filters for efficient air filtration.