Your raw agricultural commodities—be it corn, wheat, cassava, or potatoes—hold far more value than their initial market price suggests. The key to unlocking this potential is the Starch Processing Machine.

The most profitable application of the starch processing plant is its ability to convert primary starch into a range of lucrative derivatives. By integrating different processing modules—such as hydrolysis, isomerization, and hydrogenation—a single plant can create specialized products that command premium prices:

Sweeteners: Transforming starch into glucose (dextrose), high-fructose corn syrup (fructose), and syrups essential for the beverage and confectionery industries.

Sugar Alcohols: Producing sorbitol, a sugar alcohol widely used as a sweetener and humectant in pharmaceuticals, cosmetics, and health foods.

Industrial Starches: Modifying starch into specialty thickeners, binders, and coatings for paper, textiles, and adhesives.

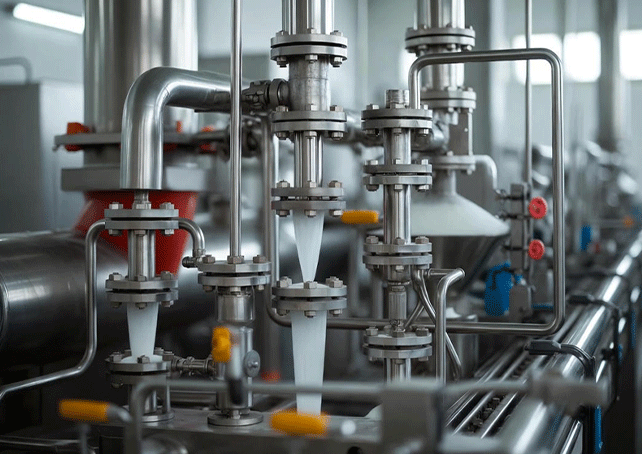

A modern Starch Processing Machine is designed for holistic efficiency, ensuring virtually zero waste and maximizing revenue from every part of the raw commodity. The system leverages physical separation principles (insolubility and specific gravity differences) to isolate not just the starch, but crucial by-products as well:

Protein and Gluten: High-quality protein and gluten are efficiently recovered, often sold as valuable animal feed supplements or ingredients for specialty food products.

Fiber: Remaining fiber is often processed into feed or used as fuel in the plant's boiler system, further reducing operational costs.

This multi-product recovery approach ensures that the entire system acts as a profit center, turning former waste streams into revenue streams.

The high efficiency and yield of automated Starch Processing Machines are intrinsically linked to their ability to deliver consistent quality control.The entire extraction, purification, and refining process is monitored and controlled by precise, automated systems.

This level of control ensures:

High Purity: Starch is purified to exacting standards required by pharmaceutical and high-grade food applications.

Product Consistency: Every batch of glucose, fructose, or sorbitol meets the required specifications in terms of concentration, color, and chemical properties, a non-negotiable requirement for major industrial customers.

This advanced industrial system is not just about extracting basic starch; it's a comprehensive EPC (Engineering, Procurement, and Construction) solution that transforms raw material into a diverse portfolio of high-value, market-ready products. Deploying this technology is the definitive strategy for maximizing yield, ensuring quality, and dominating competitive food, chemical, and pharmaceutical markets.